Making lithium batteries involves several intricate steps and the careful assembly of various components.

Here's a comprehensive breakdown of the process:

Part 1: How Lithium Batteries are Made

Step 1: Making Electrode

Materials: Cathode materials like lithium cobalt oxide (LiCoO2), lithium iron phosphate (LiFePO4), or nickel-manganese-cobalt oxide (NMC); Anode materials typically graphite or sometimes silicon.

Process:

Materials are mixed with conductive binders and solvents to form a slurry.

Slurry is coated onto metal foils (cathode on aluminum, anode on copper) using tools like slot dies or doctor blades.

Step 2: Drying and Cutting

Drying: Coated foils are dried in ovens to remove solvents.

Cutting: Electrode sheets are cut to precise shapes and sizes using slitting machines.

Step 3: Stacking and Filling

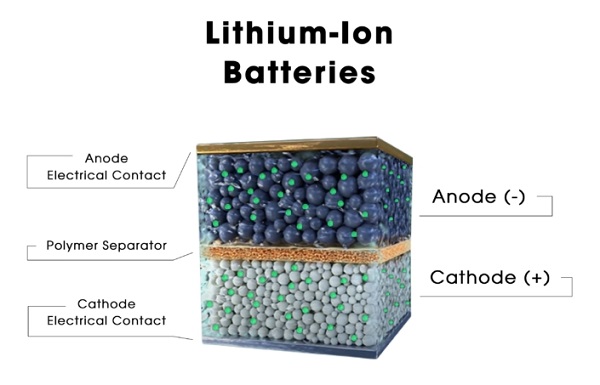

Stacking: Electrodes (cathode and anode) and separators (polyolefin-based) are assembled in the desired configuration (cylindrical, prismatic, etc.).

Filling: Electrolyte (lithium salt dissolved in organic solvent) is injected to facilitate ion movement between electrodes.

Step 4: Sealing and Formation

Sealing: Battery casing is sealed using heat sealers or laser welding machines to prevent leakage.

Formation: Battery undergoes initial charging and discharging cycles to stabilize performance and establish a solid electrolyte interface (SEI).

Step 5: Final Testing

Batteries undergo rigorous testing for capacity, charging speed, discharging rate, temperature resistance, and overall performance metrics.

Part 2: Raw Materials for Lithium Batteries

Cathode Material: Provides positive electrode:

Lithium cobalt oxide (LiCoO2)

Lithium iron phosphate (LiFePO4)

Nickel-manganese-cobalt oxide (NMC)

Anode Material: Provides negative electrode:

Graphite (commonly used)

Silicon (used in some advanced batteries)

Separator Material: Provides safety barrier between electrodes:

Polyethylene

Polypropylene

PVC or blends of these materials

Electrolyte Material: Facilitates ion flow between electrodes:

Lithium salt dissolved in organic solvent (e.g., ethylene carbonate)

Part 3: Making Lithium Cells

The process for making lithium cells follows similar steps as making lithium batteries but on a smaller scale. It involves:

Mixing electrode materials into slurry.

Coating slurry onto current collectors.

Drying, cutting, stacking, filling, sealing, and testing as described above.

Part 4: Assembling Lithium Battery Packs

Cell Selection:

Selecting cells with uniform capacity, chemistry, and voltage for consistent performance.

Configuration:

Cells can be connected in series for increased voltage or in parallel for increased capacity.

Welding Lithium Cells:

Cells are joined using spot welding or soldering, ensuring proper insulation and safety precautions.

Insulation and BMS Installation:

Battery cells are insulated and placed in a protective casing.

Battery Management System (BMS) is installed to monitor and manage cell performance, preventing overcharging or deep discharging.

In summary, the manufacturing of lithium batteries involves precise handling of materials and processes to ensure performance, safety, and reliability in various applications from small electronic devices to large-scale energy storage systems.