A high-rate battery means that the battery can be discharged at a high current. The high-rate charge-discharge performance of a lithium battery is closely related to the migration ability of lithium ions at the electrode, electrolyte and their interface. All factors affecting the migration speed of lithium ions will definitely affect the high rate of the battery Charge and discharge performance.

Advantages of high-rate lithium-ion batteries

① It has the characteristics of excellent high-current discharge performance, sufficient power, high discharge platform, and good cycle life;

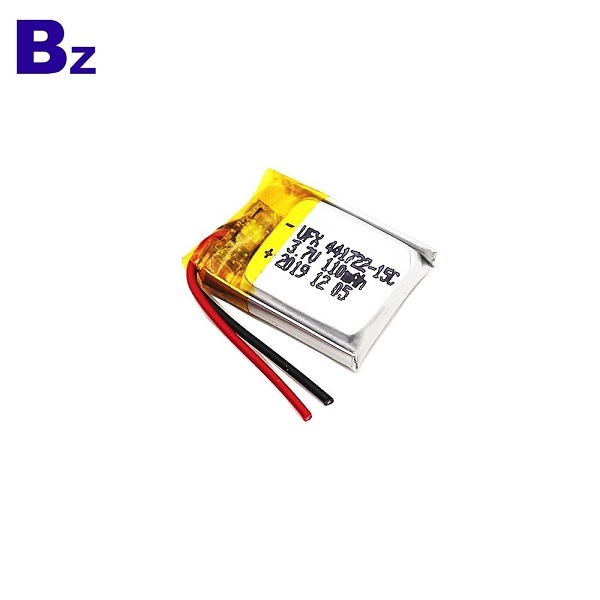

② It has high energy density and adopts lamination technology. Because of its low internal resistance, it is more conducive to high rate charge and discharge and high efficiency output performance;

③ Supply a higher discharge rate, up to 45C, and have better temperature stability during discharge, which is controlled within 65 degrees Celsius to prevent overheating and damage;

④ The lithium-ion battery is ultra-thin, small in size, and extremely light in weight. It can be made into special-shaped batteries of various shapes and capacities, and the thickness can be 0.45mm.

High-rate lithium-ion battery applications

There are three main types of high-rate lithium-ion batteries: lithium iron phosphate batteries, polymer lithium-ion batteries, and nickel-hydrogen batteries. The first two are in the form of soft-packed aluminum-plastic film, and the last one is cylindrical in steel shell. These three kinds of high-rate batteries are widely used in 3C electronic products, model entertainment and sports, power tools, drones, industrial power supplies and other fields.

With the development of the industry, there is a demand for higher rate and faster charging of lithium-ion batteries, which has promoted the technological improvement and application of high rate batteries. At present, high-rate batteries are widely used in aerial photography drones, agricultural plant protection drones, emergency starting power supplies, model airplanes, power tools, etc.

There is a layer of SEI film on the surface of the negative electrode of a lithium battery. In fact, the rate performance of a lithium battery is largely controlled by the diffusion of lithium ions in the SEI film. Since the polarization of the powder electrode in the organic electrolyte is much more serious than that of the water system, lithium is prone to be deposited on the surface of the negative electrode under high-rate or low-temperature conditions, which brings serious safety hazards. In addition, under high-rate charging conditions, the crystal lattice of the positive electrode material is easily damaged, and the graphite sheet layer of the negative electrode may also be damaged. These factors will accelerate the attenuation of the capacity and seriously affect the service life of the lithium-ion battery.

High-rate lithium-ion batteries are suitable for use in some light equipment, to achieve rapid increase in the operating speed of the equipment, such as competitive drones, light track racing, water electric skateboards, etc.; or used in some power tools, such as electric drill tools. As long as the high-rate discharge in a short time is enough to make the fasteners loose. High-rate lithium-ion batteries are currently unable to provide long-lasting high-current discharge, which can easily cause failures or accidents when the battery is too high temperature.